Supply chains are like rows of dominos.

Pandemics, geopolitical unrest, recessions, and natural disasters – seemingly the only things in abundant supply right now – can knock over any one of them, setting havoc in motion across nations. Before you know it, automakers in Baden-Württemberg are out of semiconductors and Silicon Valley is out of microchips.

The words “supply chain” entered the global consciousness at the same time as the words “pandemic” and “quarantine”. Firstly when we realised we didn’t have enough respirators, then when the loo roll started running out.

Globalisation used to mean cheap manufacturing and affordable consumer products for all. Now, it means a concerning reliance on faraway nations and the supply chains that connect us to them.

The wheels are already faltering in the face of global pressures. How can the supply lines that are so reliant on predictability adapt to an increasingly unpredictable world?

Behind the scenes

Freight, logistics, transportation: the invisible engines that kept the world turning, but not particularly exciting concepts to the average person.

When petrol prices jump, supermarket shelves empty, and our next-day Amazon deliveries delay into next week, we suddenly start to pay attention.

Electric cars are making in-roads (sorry) on our fossil fuel reliance, saving roughly 1.5 million barrels of oil every day. But Australia still guzzles 1 million barrels of petrol and diesel every day.

80% of it comes from overseas – mainly the Middle East – and is refined in Singapore, Japan, and South Korea. 50% of what you pay at the pump is benchmarked retail prices (what it costs to purchase the crude oil). The other 50% covers storage, transport, taxes (high), and profit margins (surprisingly low – gas stations tend to make more from food and drinks).

Russia produces 11% of the world’s oil. Because of American sanctions, that 11% has left the market, causing other providers to hike up their prices. The problem is that oil trade runs like the stock markets. Traders buy speculatively, betting on prices going up or down, or even shorting it. Because they believe prices will stay high due to the ongoing conflict, they pay more, so we pay more.

It’s similar with agricultural commodities like wheat. Fruit and veg went up by 6.7% following the East Coast floods. When crops can’t be distributed or are destroyed by natural events, it’s the food insecure who suffer first.

What do we do about it?

Homegrowing

Homesteading, veggie growing, and community gardens are a wonderful new trend. If you can, it makes sense to grow your own beans and tommies just in case. But it’s a privilege most city dwellers can’t afford.

On an industrial scale, simply going back to farming local is a problem for three major reasons:

1. Supply will regulate, which will eventually leave us with a surplus

2. Nations will lose vast amounts of national income in exports

3. Climate change is making it increasingly impossible to grow certain products.

Agriculture is already in crisis due to growing veganism and vegetarianism, eroding topsoil, and (justified) sustainability pressures. Government subsidies aren’t enough to keep farmers in business.

As with most things, balance is the answer. Flexible importing and exporting that can fluctuate in line with lack and surplus. Hydroponics and vertical farming offer a possible solution.

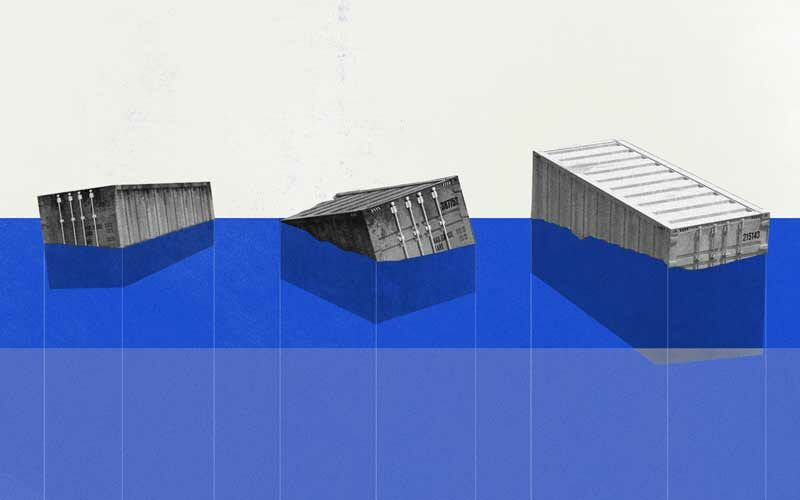

Independent chartering

In the pandemic years, several global firms including IKEA, Home Depot, and Walmart addressed the global supply chain crisis and its associated costs by simply doing it themselves.

Now, Lidl has registered a container shipping arm called Tailwind Shipping Lines. Apple has shifted iPad production from China to Vietnam. Drinks companies are turning to ‘less than container load’ (LCL) services, where multiple vendors with smaller than average shipments can share shipping (that’s if they can get hold of glass bottles in the first place).

Government intervention

Nothing oils a supply chain like democracy. In 2021, at the Group of Seven summit in Cornwall, UK, President Biden attempted to address shortages of things like minerals, semiconductors, and PPE with a hybrid proposal.

Biden’s plan was to “break down bottlenecks” and “reverse the race to the bottom”. He’s making good on his word. So far this year:

- America’s Export-Import Bank will prioritise financing and provide export credits for ‘critical export items’ distributed by US SMEs abroad.

- New ‘Buy American’ provisions enable the US government to buy domestically produced goods at higher rates than foreign goods.

- The DOE is providing extra funding for tech that “facilitate[s] a decarbonized future”.

- The American Rescue Plan will leverage $1 billion to enhance processing capability in agriculture.

The problem with Australia is that we can only get stuff here with ships and planes (not trains or automobiles). What compounds it is poorly regulated shipping lines realising their opportunity and “colluding” to raise prices (in some cases “tenfold”). So what’s the Australian Government doing about it?

- Building a vague-sounding “AUS-UK joint supply chain resilience capability” that boosts resilience and enhances transparency

- Providing $50,000 to $2 million grants to help businesses with supply chain vulnerabilities – but this has now closed

- Blaming the shipping companies.

Disruption

Thankfully, we have startups.

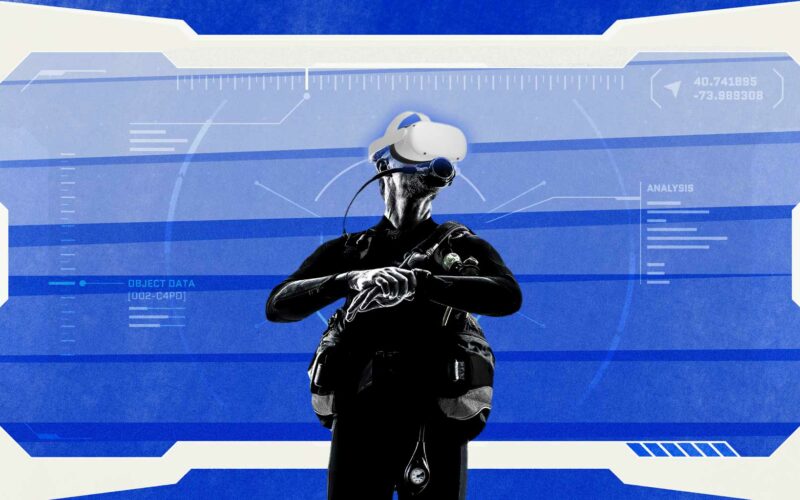

Global VC investment in “FreightTech” increased from USD $1.3 billion to $2.9 billion in 2018. The wider industry could be worth $20 billion by 2025, and 80% of them will use AI and data science “in some way”.

This is not freight as we know it. This new breed of shifters and shippers is characterised by intelligence, automation, and integration. The space is ripe for data-driven decision making. AI is reducing physical labour. And platform models are increasing transparency and communication.

New FreightTech startups have “digital DNA”. they’re not adopting the IoT, apps, or cloud software – they’re built on them. Their structures are lean, their working style agile. 10 years ago, few industries were as asset heavy as freight. But some of the born-digital breed are asset light or even asset zero thanks to innovative vehicle hiring models.

In Explorate cofounder Conor Hagan’s words: “The information flow required to ship goods around the world is becoming increasingly complex”. Explorate’s platform model tackles this by comparing rates and sailing times, simplifying complicated shipments, and assessing carbon impact.

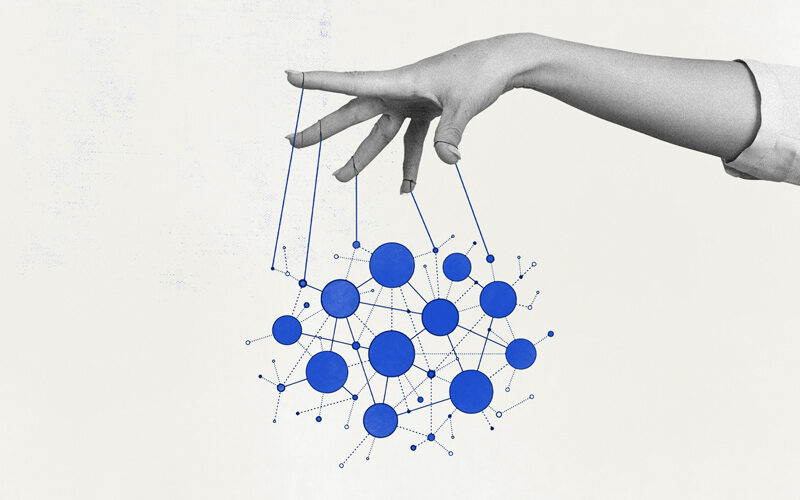

US unicorn Interos uses machine learning (ML) to monitor 400 million businesses worldwide and alert its customers when natural disasters, security breaches, or conflict may affect them. Interos assessed the potential impacts of the Russian invasion before it happened. 700 companies approached them for guidance when the war broke out.

Chief Executive Jennifer Bisceglie has announced development of a new product that will “game out other hypothetical supply chain disruption scenarios, such as China invading Taiwan” so customers can “understand their exposure to risk and where to find alternative suppliers”. Essentially, preparation is better than cure.

Like with so much failed (or never initiated) policy, innovating our way out of a supply chain crisis has fallen to startups. They have the tools to make primitive old supply chains leaner, faster, and stronger.

Who knows, maybe we’ll one day see a world where we never run out of loo roll again.